Brass, an alloy of copper and zinc, is one of the oldest and most widely used alloys in human history. This alloy has been used in various industries due to its unique properties, including beautiful color, high ductility, corrosion resistance, and good electrical and thermal conductivity. As a raw material in the production of rice products, rice ingots are of particular importance. In this article, we will examine this product, its production process, its types and applications.

Definition of rice ingots

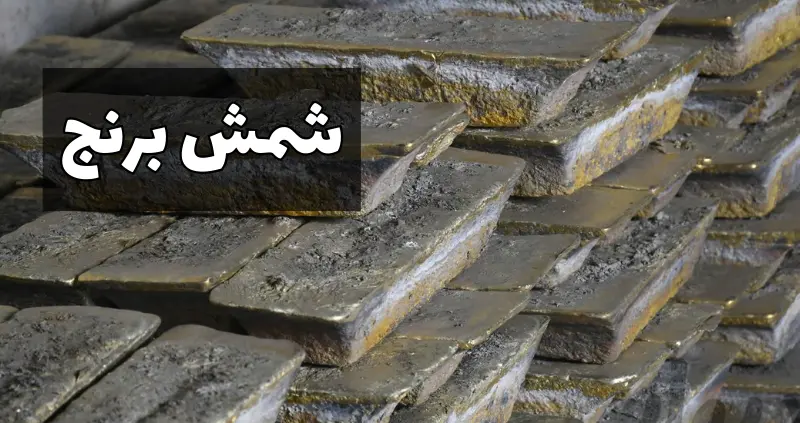

Brass ingots are large blocks of brass alloy that are used as a raw material for the production of brass products and parts. These lice can be produced in different sizes and shapes, and depending on the ratio of copper and zinc in the alloy, they have different properties.

The process of producing rice ingots

The production of rice ingots begins with the combination of copper and zinc in certain proportions. This process includes the following steps:

Melting down: Copper and zinc are melted in furnaces in the desired proportions. Melting temperature must be carefully controlled to prevent zinc evaporation and impurity formation.

Refinement: The melt obtained from melting is passed through purification processes to remove impurities to obtain a high purity alloy.

Casting: The purified melt is transferred to casting molds to form rice ingots. After cooling, the ingots are ready to use.

Types of rice ingots

Based on the ratio of copper to zinc and other elements that may be added to the alloy, brass ingots are divided into different types. Some of these types are:

- Yellow rice: With more zinc, it has a yellow color and different mechanical properties.

- Red rice: It has more copper and shows more resistance to corrosion.

- Special rice: which is produced by adding other elements such as lead to improve machinability.

Uses of rice ingots

Rice ingots are used in the production of various products and brass parts, including:

Kitchen and decorative accessories: Due to its natural beauty and corrosion resistance, it is used to make kitchen utensils, locks, handles and decorative objects.

electrical equipment: Due to its high electrical conductivity, it is used in making connections, sockets and other electrical parts.

Construction: It is used in the production of pipes, valves and fittings due to its high resistance to erosion and corrosion.

Challenges and the future

One of the main challenges in the production of brass ingots is the precise control of alloy proportions and maintaining the quality of the alloy. Also, considering the limited resources of copper and zinc, the recycling of this product and brass products has become very important.

The future of this product depends on technological innovations in production and recycling processes. By developing more sustainable and efficient methods, we can ensure that this product remains a key resource in various industries.

Conclusion

As a raw material in the production of various products and brass parts, rice ingots play an important role in industry and production. From kitchen utensils to electrical equipment and construction, there are wide applications for this alloy. With technological advances and a focus on sustainable methods, we can be sure of a bright future for the use of this product in various industries.

Read more: Aluminum ingot